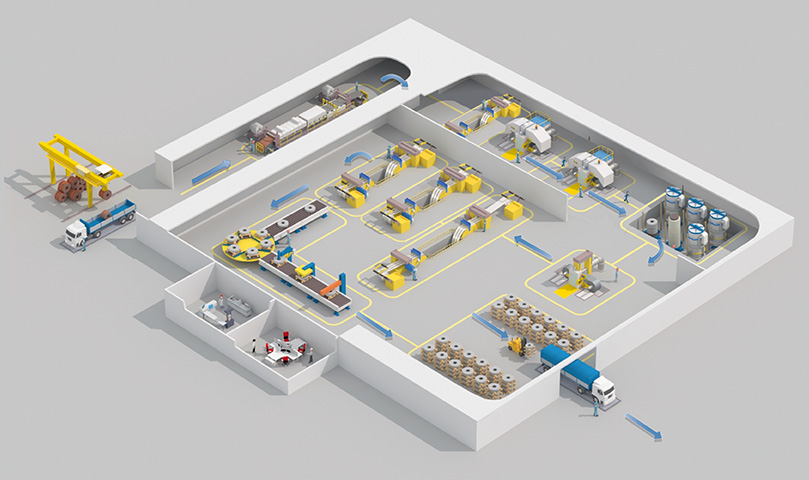

PLANT

Manufacturing

PRODUCTION

EMPLOYEES

RAW MATERIAL STORAGE

A surface area of 3000 m2 organised by a last generation automated crane. The surface storage area has a capacity of 18,000 mT, (approximately 800 coils). In addition, we have a integrated software management system running throughout the process.

PICKLING LINE

Descaling through immersion in HCL (hydrochloric acid) utilising a push-pull system. The integrated longitudinal slitting line at the end of the process optimises the lead time (2 steps in 1).

- Maximum width : 1.500 mm

- Minimum width : 800 mm

- Min. thickness : 1 mm

- Max. thickness : 7 mm

- Maximum weight : 25 Tm

ROLLING MILLS

We have two quarto reversible mills, with x-ray thickness measurement and laser controlled speed. Our rolling mills are High precision in thickness tolerance, based on the perfect definition of the thickness and velocity measurement systems.

T1

- Width : 450 a 800 mm

- Output thickness (mín) 0,2 mm

- Maximum input thickness 9,00 mm

- Max exterior Ø : 2.000 mm (23 Kg/mm)

- Maximum speed : 900 m/min

T4R

- Width : 450 a 750 mm

- Output thickness (min) 0,2 mm

- Maximum input thickness 7,00 mm

- Max exterior Ø : 1.800 mm (18,4 Kg/mm)

- Maximum speed : 1.100 m/min

ANNEALING FURNACES

Our factory has high convection annealing furnaces in a protective atmosphere of Hydrogen (H2). The high convection system and the hydrogen atmosphere give us high uniformity in the mechanical characteristics of the material, as well as optimal surface cleanliness

- No. of bases: 22

- No. of furnaces: 12

- No. cooling chambers: 11

- Maximum 65 mT/base

SKIN PASS

A four cylinder Mill, and integrated final gauge measurement using radioisotopes, together with the use of antioxidant thixotropic oils, and the precision surface finish working cylinders guarantee a high quality final product.

- Width: 450 a 750 mm

- Thickness: 0,20 a 6,00 m

- Max exterior Ø 1800 mm (18,4 Kg/mm)

- Max speed: 500 m/min

LABORATORY

Our laboratory is focussed on the needs of our customers: the different product analyses that guarantee the highest quality and, of course, the fulfillment in design specification. Innovation maintains us at the leading-edge and enables us to offer technical assistance and join development with our customers.

The high quality requirements our customers demand and our commitment to develop high precision products has led us to implement internal management systems in the fields of safety, quality and the environment, backed by the following certifications:

CERTIFICATIONS:

- ISO 45001:2018

- ISO 9001:2015

- IATF 16949:2016

- ISO 14001:2015

- ISO 50001:2011

SLITTING LINES

We have 4 integrated longitudinal cutting lines. The automatic change of the cutting body, the detection and finishing systems of the installations enable a high quality of the final strip, combined with high cutting productivity.

- No. of shears: 4

- Cutting width: 14 – 1.350 mm

- Thicknesses of: 0,20 a 9,00 mm

- Output ext Ø: from 850 to 1.800 mm

- Max speed.: 300 m/min

PACKAGING

The packaging line is totally automated and guarantees the highest product quality, along with high productivity and safety, avoiding human handling throughout the process.

LOGISTIC AREA

ARANIA has the latest technology in logistics, handling and control of finished products. The entire process is controlled by software, which allows us to guarantee excellent agility and speed of despatch.

This process results in fast lead times for deliveries to any location.